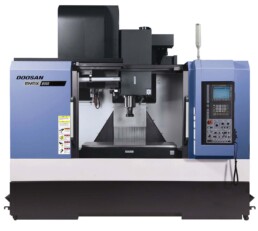

Latest generation multi axis Machining Centers To Meet Exact Customer Specifications

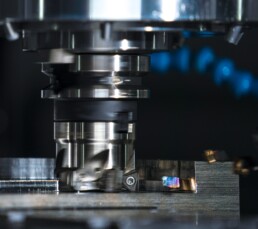

From milling,turning,boring to drilling, our engineers select the ideal equipment for an application based on the geometry, material, and volume of the part being machined to provide customers with premium quality parts at the best possible price. Secan’s rough machining and finish machining capabilities with multi axis machines can meet the most demanding customer requirements.

These capabilities extend not only to standard dimensions but also to unusual shapes and sizes such as balls, spherical configurations, as well as those calling for special tools or fixtures.

Machining at Secan is performed using computer numerical control (CNC) technology. The facility uses its full range of new generation CNC machines and latest measuring equipment’s being handled by professional & dedicated workforce in synergy between man machine methods to meet customers critical requirements and on time delivery.

Machining Capabilities

- Boring

- Drilling

- Turning

- Milling

- Oil grooving

- Lapping

- Shrink fitting