Non-Destructive Testing, Mechanical Testing & Chemical Analysis

QUALITY is one of the main features of the processes, products and services that SECAN offers its customers all over the world with a best quality.

In the process of each stage, from the design, purchase and reception of the materials, manufacturing, dispatch and the commissioning on the end-customer’s premises is supervised and controlled in line with the most demanding internal procedures and specifications of its

Quality Management System, in compliance with the ISO 9001: 2015 standard,

Energy Management System & OSHAS in compliance with the ISO 14001: 2015 standard,

Energy Management System & OSHAS in compliance with the ISO 45001: 2018 standard,

Conducting the frequent internal and external audits by customers or other monitoring bodies to review and improve the quality management process.

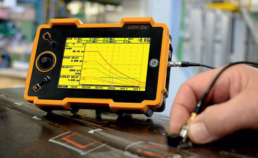

Non-Destructive Testing

SECAN undertake the following NDT (non-destructive testing) for which we are equipped with the latest quality control equipment and has accredited technicians trained in quality control techniques. On-site technicians are fully trained and certified in both NDT Level II and Level III.

NDT capabilities are as follows:

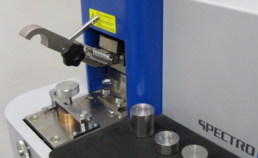

Mechnical Testing

Secan is equipped to meet a range of mechanical requirements through comprehensive mechanical testing capabilities. Our certified technicians are trained to push the mechanical limits of our components to ensure they meet the highest standards of quality and safety.

Mechanical testing capabilities include:

- Tensile testing (ambient and elevated temperatures)

- Impact testing / Charpy

- Brinell & Rockwell hardness testing

- Stress rupture

Laboratories

SECAN has 2 laboratory units offering specific features and functionalities:

- Metallurgical laboratory: chemical composition analysis, metallographic phase analysis, residual austenite content analysis, measuring of mechanical characteristics, tensile strength, breaking load, toughness and elongation.